- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

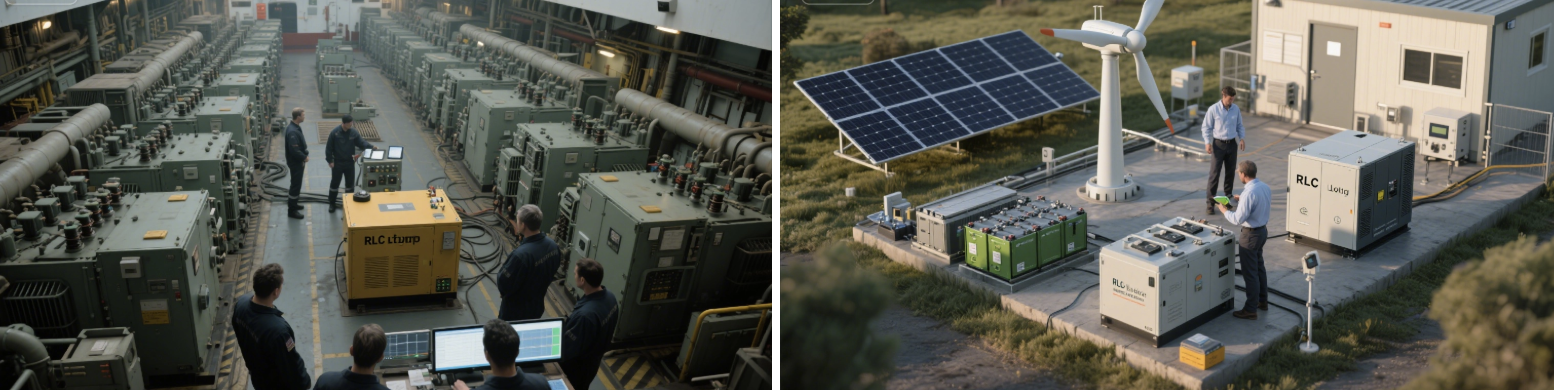

What is an RLC load bank? This versatile tool is essential for testing and evaluating electrical systems by simulating various loads. Whether you’re working with generators, UPS systems, or power distribution networks, an RLC load bank offers the precision and flexibility needed to ensure your equipment performs reliably under real-world conditions. In this guide, we’ll explore how RLC load banks work, their key benefits, and why they are crucial for maintaining efficient and safe power systems. Let’s dive in and uncover the power of RLC load banks!

An RLC load bank is a sophisticated testing device designed to simulate a wide range of electrical loads. It connects to a power source and allows for the independent or combined application of resistive, inductive, and capacitive loads. This versatility makes it an essential tool for evaluating the performance of power systems, generators, and transformers under various real-world conditions.

RLC load banks are essential tools in the electrical industry, providing a versatile and controlled method to test and evaluate the performance of power systems. Here are the key reasons why RLC load banks are used:

RLC load banks simulate a wide range of electrical loads, including resistive, inductive, and capacitive components. This allows for testing under conditions that closely mimic real-world applications. For example, inductive loads simulate motors and transformers, while capacitive loads simulate power factor correction equipment.

The ability to independently or combinedly apply different types of loads provides flexibility. This customization enables detailed performance evaluations under various operating conditions, ensuring that power systems can handle different types of loads efficiently.

Generators need to be tested regularly to ensure they can handle the loads they are designed for. RLC load banks provide a controlled environment to test generators under different load conditions, ensuring they perform reliably during emergencies or peak demand periods.

Transformers are critical components in power distribution systems. RLC load banks help evaluate the efficiency and reliability of transformers under various load conditions, ensuring they operate safely and efficiently.

RLC load banks help in balancing the load on power systems. By simulating different types of loads, engineers can optimize the distribution of power, ensuring that the system operates efficiently and avoids overloading.

Capacitive loads in RLC load banks can simulate power factor correction equipment. This helps in evaluating the effectiveness of power factor correction measures, ensuring that the power system operates at optimal efficiency.

An RLC load bank is a versatile testing tool that connects to a power source and allows for the independent or combined application of resistive, inductive, and capacitive loads. This multifunctional device is designed to simulate various types of electrical loads, making it an essential tool for testing and evaluating the performance of power systems, generators, and transformers.

Resistive Elements (Heating Coils): These components simulate real power consumption. They convert electrical energy into heat, providing a stable and predictable load profile.

Inductive Coils (Air-core or Iron-core Reactors): These simulate lagging power factor loads, such as those found in motors and transformers. Inductive loads cause the current to lag behind the voltage, creating a reactive power component.

Capacitive Banks (Capacitor Arrays): These simulate leading power factor loads. Capacitive loads cause the current to lead the voltage, providing a reactive power component that can counteract inductive loads.

Control Panels for Adjusting Load Steps: These panels allow operators to precisely control the amount of resistive, inductive, and capacitive load applied to the power source. This flexibility enables detailed testing under various conditions.

Monitoring Systems for Voltage, Current, Power Factor, and Frequency: These systems provide real-time data on the performance of the power source. They help ensure that the load bank is operating within safe and effective parameters.

Forced Air Cooling Systems for Heat Dissipation: These systems manage the heat generated by the resistive elements, ensuring that the load bank operates efficiently and safely.

A 500 kW RLC load bank may allow:

300 kW Resistive Load: Simulates real power consumption.

150 kVAr Inductive Load: Simulates lagging power factor loads.

150 kVAr Capacitive Load: Simulates leading power factor loads.

Adjustable Power Factor from 0.6 Lagging to 0.6 Leading: Provides flexibility in testing various power factor conditions.

This flexibility enables detailed performance evaluations under a wide range of real-world operating conditions. Whether you are testing a generator’s ability to handle different types of loads or evaluating the efficiency of a power system, an RLC load bank offers the precision and control needed for accurate and reliable results.

RLC load banks simulate real-world electrical loads, allowing for comprehensive validation of generator and UPS systems under varying power factors and load profiles. This ensures that these critical power systems can handle the demands placed on them during normal and emergency operations. By testing under different load conditions, engineers can verify the system’s ability to maintain stable voltage and frequency, ensuring reliable performance when it matters most.

One of the unique capabilities of RLC load banks is their ability to test systems under leading, lagging, and unity power factors. This is crucial for verifying the ability of power sources to handle reactive loads effectively. Leading and lagging power factors are common in industrial settings where inductive and capacitive loads are prevalent. By testing under these conditions, engineers can ensure that the power system operates efficiently and avoids potential issues such as voltage drops and harmonic distortions.

In systems where multiple generators or UPS units operate in parallel, load sharing is essential for maintaining stability and efficiency. RLC load banks help verify that each unit shares the load correctly, preventing overloading and ensuring balanced operation. This is particularly important in data centers, hospitals, and other critical facilities where uninterrupted power supply is paramount.

Regular testing with RLC load banks helps identify hidden issues such as voltage drops, harmonic distortions, and frequency instabilities before they become critical. This proactive approach ensures that power systems operate safely and reliably, reducing the risk of unexpected failures and downtime. By simulating real-world conditions, engineers can fine-tune system parameters and ensure optimal performance under various operating scenarios.

RLC load banks are versatile tools with a wide range of applications across various industries. Their ability to simulate different types of electrical loads makes them essential for testing, commissioning, and maintaining power systems. Here are some key applications:

Testing Backup Power Systems: Data centers rely on uninterrupted power supply (UPS) systems and backup generators to maintain operations during power outages. RLC load banks simulate real-world loads to test these systems, ensuring they can handle the required power demands without failure. This helps in verifying the reliability of transfer switches and the overall backup power infrastructure.

Verifying Transfer Switches: Transfer switches are critical components that switch between primary and backup power sources. RLC load banks help test these switches under different load conditions, ensuring seamless transitions and preventing data loss during power transfers.

Testing Inverters: In solar and wind power systems, inverters convert DC power from renewable sources to AC power for the grid. RLC load banks simulate grid conditions to test the performance and efficiency of inverters under various power factors and load profiles.

Battery Storage Systems: Energy storage systems, such as batteries, need to be tested for their ability to deliver power under different load conditions. RLC load banks help verify the performance and reliability of these systems, ensuring they can support grid stability and provide backup power when needed.

Microgrid Stability: Microgrids integrate multiple energy sources and storage systems to provide localized power. RLC load banks are used to test the stability and reliability of microgrids under different operating conditions, ensuring they can operate independently or in parallel with the main grid.

Commissioning Shipboard Power Systems: Ships and offshore rigs rely on complex power systems to support their operations. RLC load banks are used during commissioning to test generators, transformers, and distribution systems under various load conditions, ensuring they can handle the demands of onboard equipment and machinery.

Testing Emergency Generators: Emergency generators on ships and offshore platforms must be reliable in case of power failures. RLC load banks help test these generators under different load profiles, verifying their ability to provide power during emergencies.

Feature | RLC Load Bank | Resistive Load Bank |

Load Type | Resistive + Reactive (Inductive + Capacitive) | Resistive only |

Power Factor Testing | Adjustable, leading/lagging | Not possible |

Application Complexity | Advanced testing | Basic testing |

Material Dissipation | Heat + reactive simulation | Heat only |

Testing Accuracy | High, simulates real conditions | Limited |

Cost | Higher | Lower |

When comparing RLC load banks to resistive load banks, the key differences lie in their capabilities and applications. RLC load banks offer a more comprehensive testing solution by providing both resistive and reactive (inductive and capacitive) loads, allowing for adjustable power factor testing under leading and lagging conditions. This makes them ideal for advanced testing scenarios where realistic load conditions are crucial. They simulate both heat and reactive power, ensuring high accuracy in testing and better alignment with real-world conditions.

On the other hand, resistive load banks are simpler and more cost-effective, providing only resistive loads. They are suitable for basic testing needs where reactive power simulation is not required. While they are less expensive, their testing accuracy is limited to resistive loads only, making them less versatile for complex applications.

In summary, RLC load banks are superior for detailed and accurate testing of power systems, especially in industries requiring simulation of real-world electrical loads. Resistive load banks, while more affordable, are best suited for basic testing needs where reactive load simulation is not necessary.

When investing in an RLC load bank, consider:

Power Rating: Match with your generator or UPS output.

Voltage and Frequency Compatibility: Ensure the load bank aligns with your system’s parameters.

Step Load Control: Choose a unit with fine-grain load step adjustments for precision.

Cooling Method: Ensure adequate forced air cooling for high-power operations.

Portability: For field testing, mobile load banks may be required.

Monitoring and Data Logging: Modern load banks should offer remote monitoring, IoT integration, and data analysis features.

Compliance: Verify adherence to IEC, IEEE, and local standards.

It tests the power source’s ability to handle real-world loads, including resistive, inductive, and capacitive components, validating performance under various power factors.

Yes, it is ideal for testing inverters, battery storage, and grid-connected renewable systems.

Typically, generators and UPS systems should be tested with load banks at least annually to ensure operational readiness.

For facilities with critical operations, such as data centers or industrial manufacturing plants, an RLC load bank is essential for realistic commissioning and preventive maintenance.

An RLC load bank is far more than a testing accessory—it is a vital tool for ensuring the operational readiness, safety, and efficiency of power systems under real-world conditions. It allows for detailed performance verification, power factor testing, and load profiling, ensuring your systems can withstand the complexities of actual load conditions.

As industries transition towards smarter energy systems and sustainable operations, testing under realistic loads becomes increasingly critical. With Guangdong Emax Electrical Co., Ltd.’s high-quality RLC load banks, you can confidently validate and maintain your power systems, ensuring seamless operation when it matters most.

Contact Emax today to learn how our RLC load banks can elevate your testing capabilities and ensure your power infrastructure operates with maximum reliability and efficiency.